INJECTION MOLDING

INJECTION MOLDING

WITH AMBITION.

WITH AMBITION.

INJECTION MOLDING

WITH AMBITION.

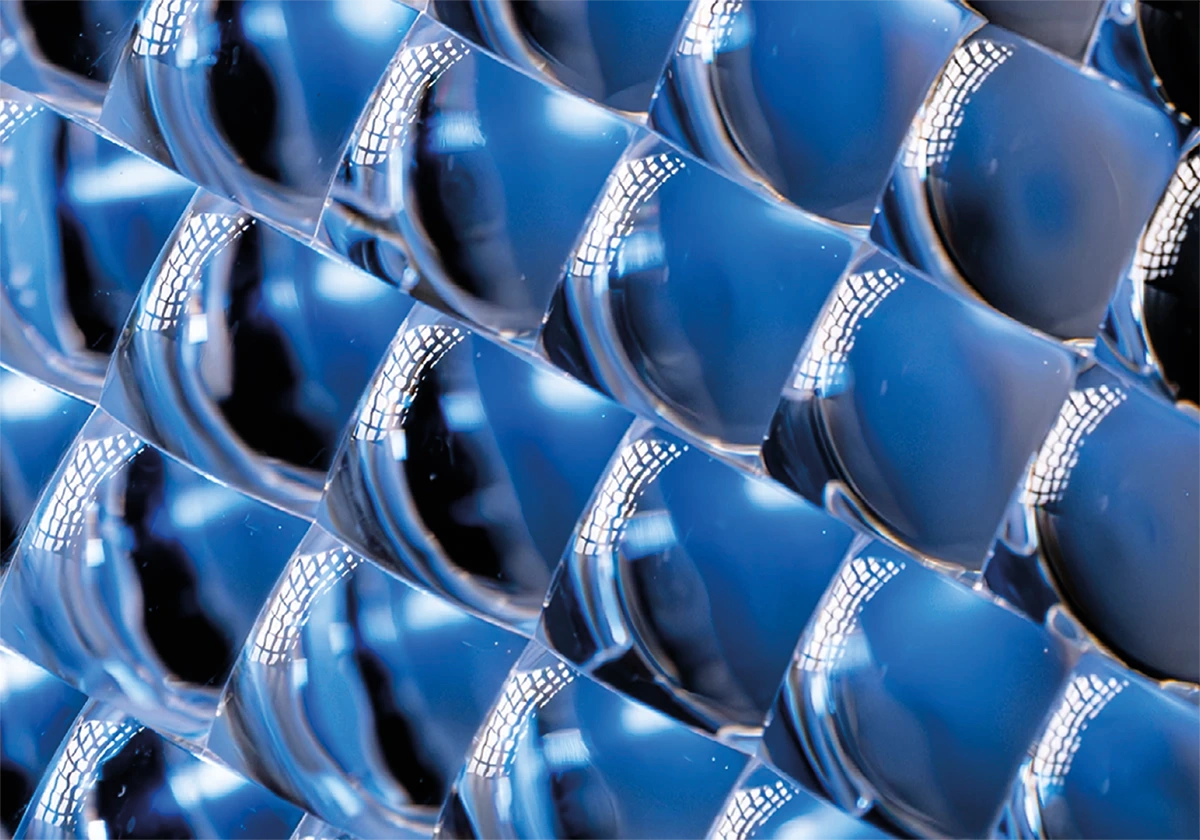

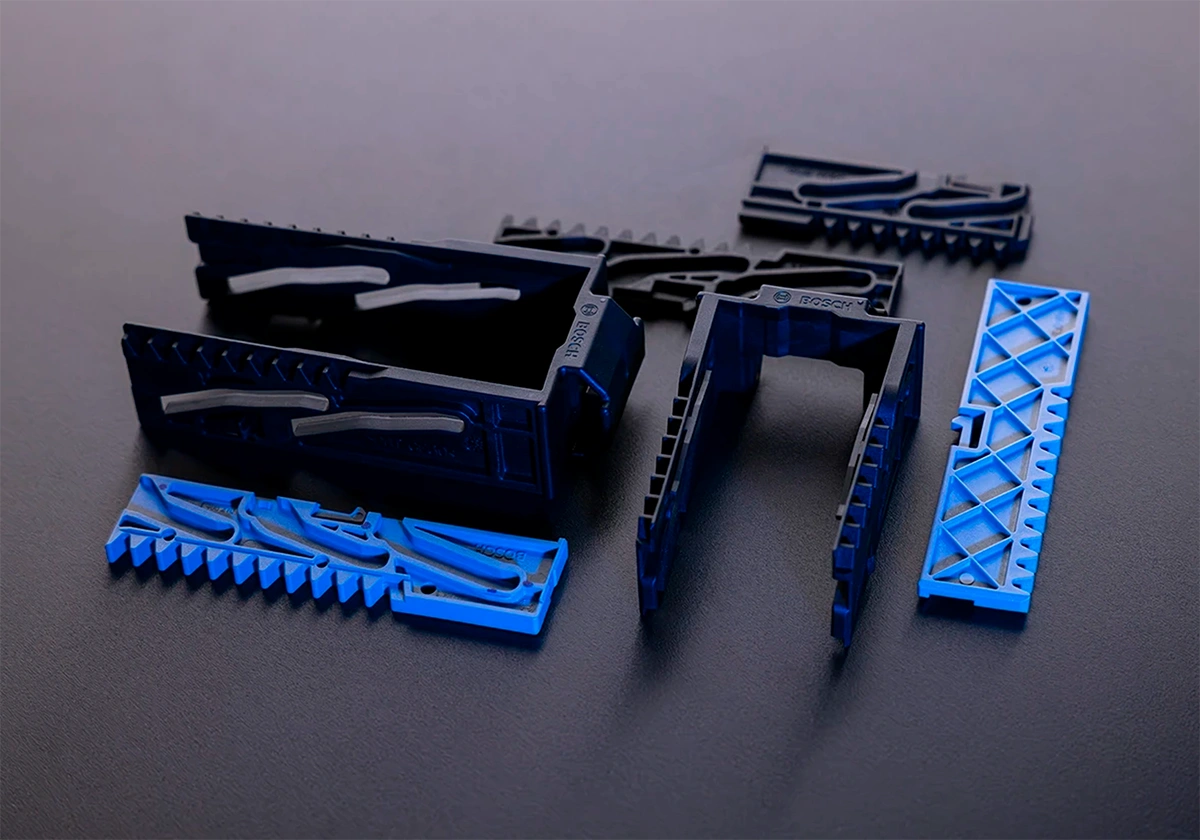

Deutsche Technoplast GmbH relies on state-of-the-art injection molding technologies. With over 90 injection molding machines featuring clamping forces ranging from 40 to 400 tons, we are capable of processing a wide variety of plastic materials. The processing of high-performance polymers such as PEEK (polyetheretherketone) and PPS (polyphenylene sulfide) is a standard part of our production process.

Deutsche Technoplast GmbH relies on state-of-the-art injection molding technologies. With over 90 injection molding machines featuring clamping forces ranging from 40 to 400 tons, we are capable of processing a wide variety of plastic materials. The processing of high-performance polymers such as PEEK (polyetheretherketone) and PPS (polyphenylene sulfide) is a standard part of our production process.

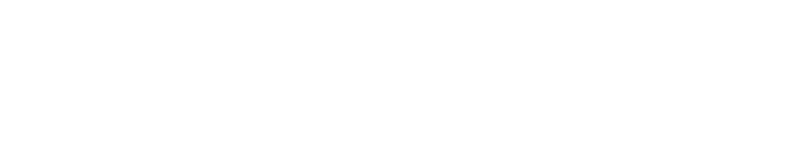

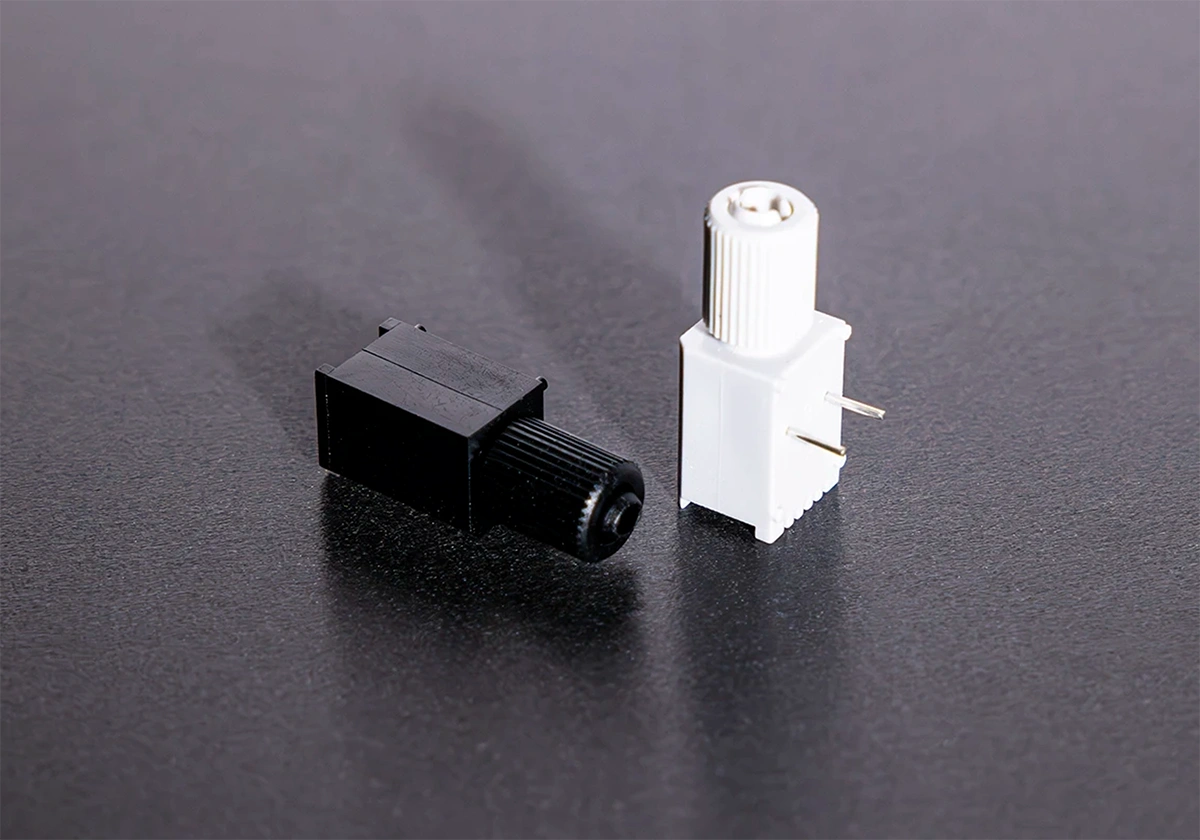

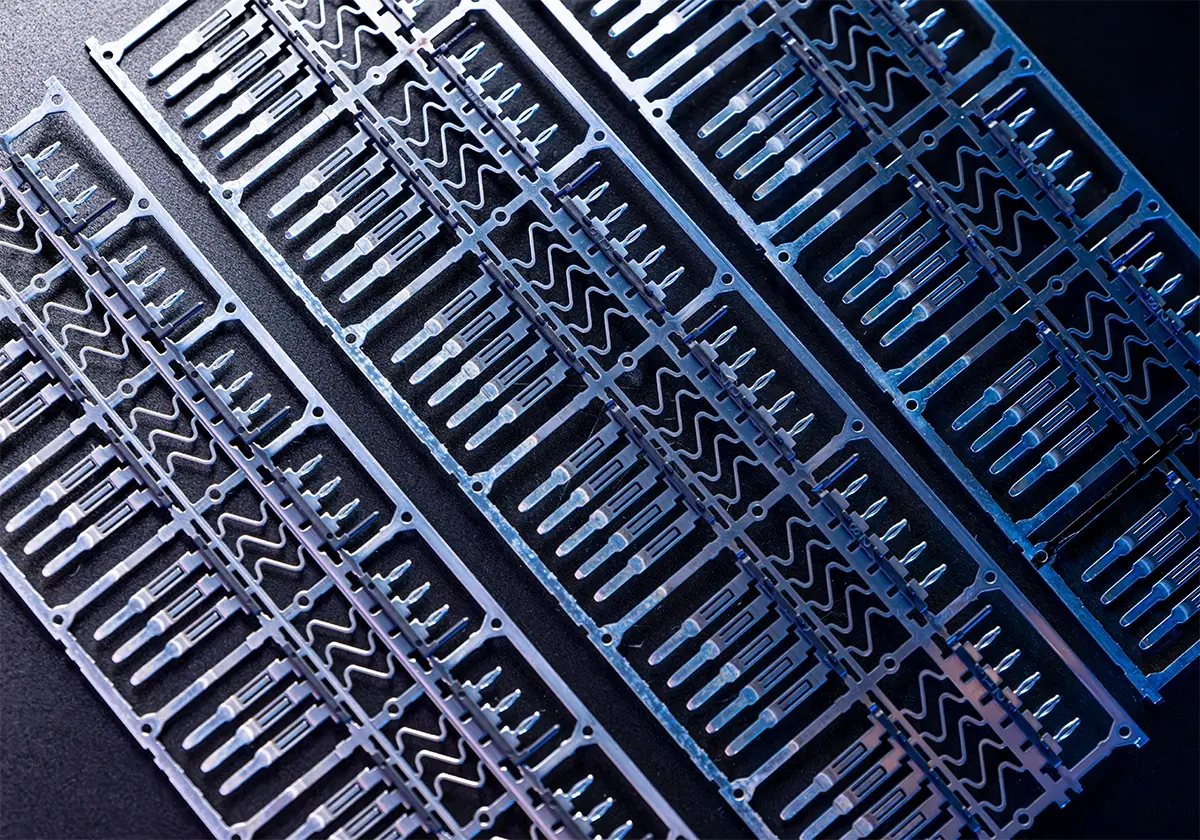

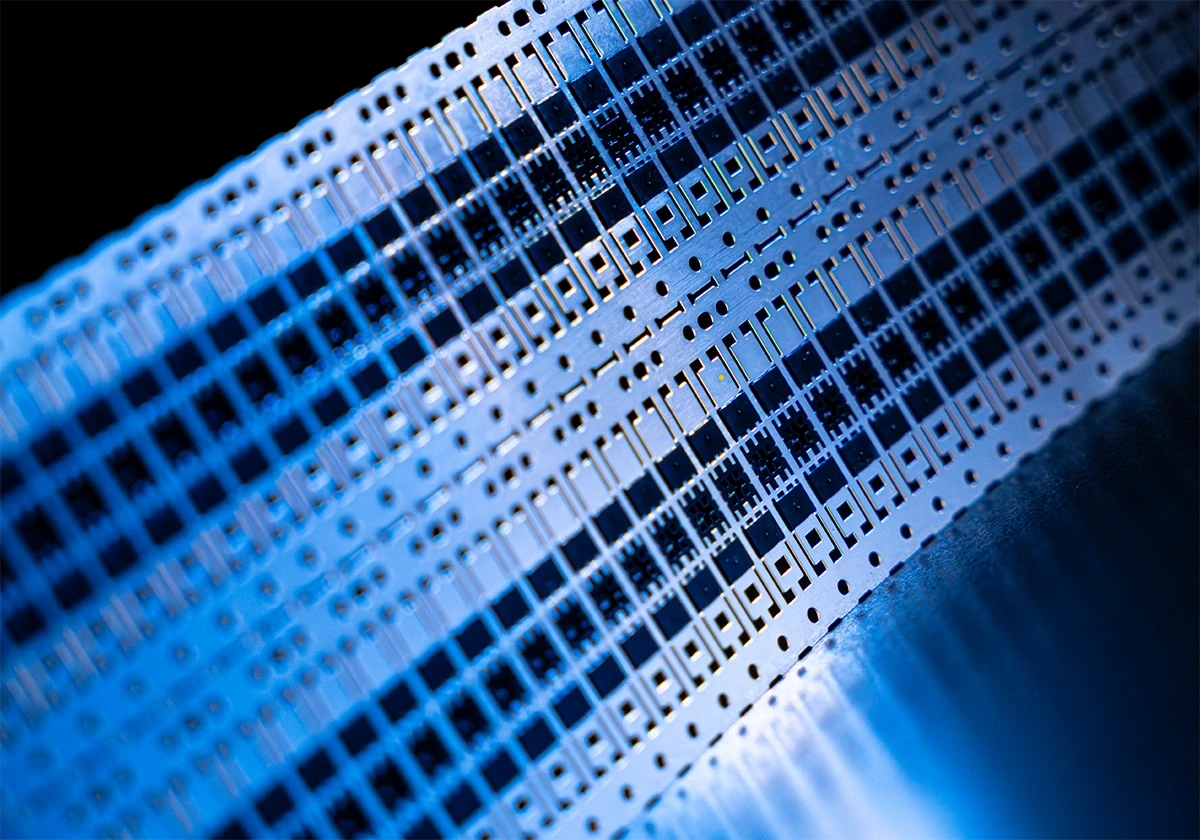

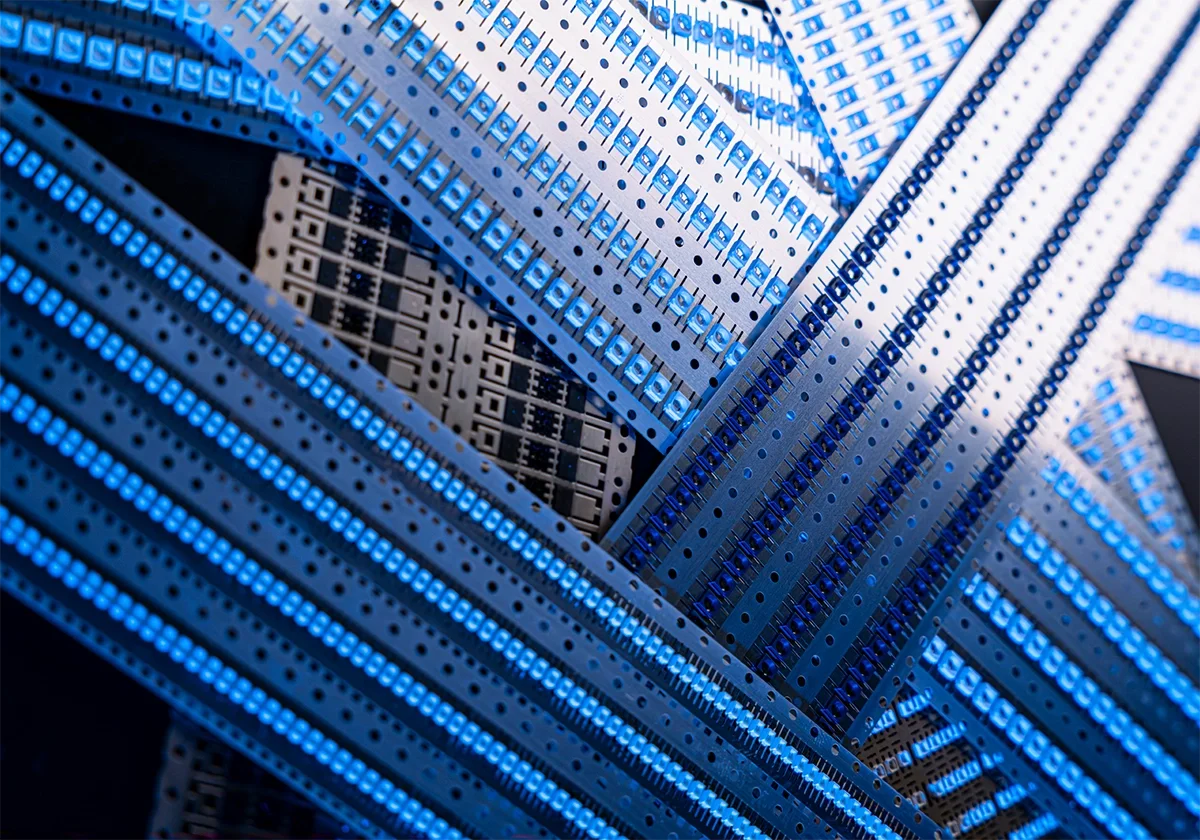

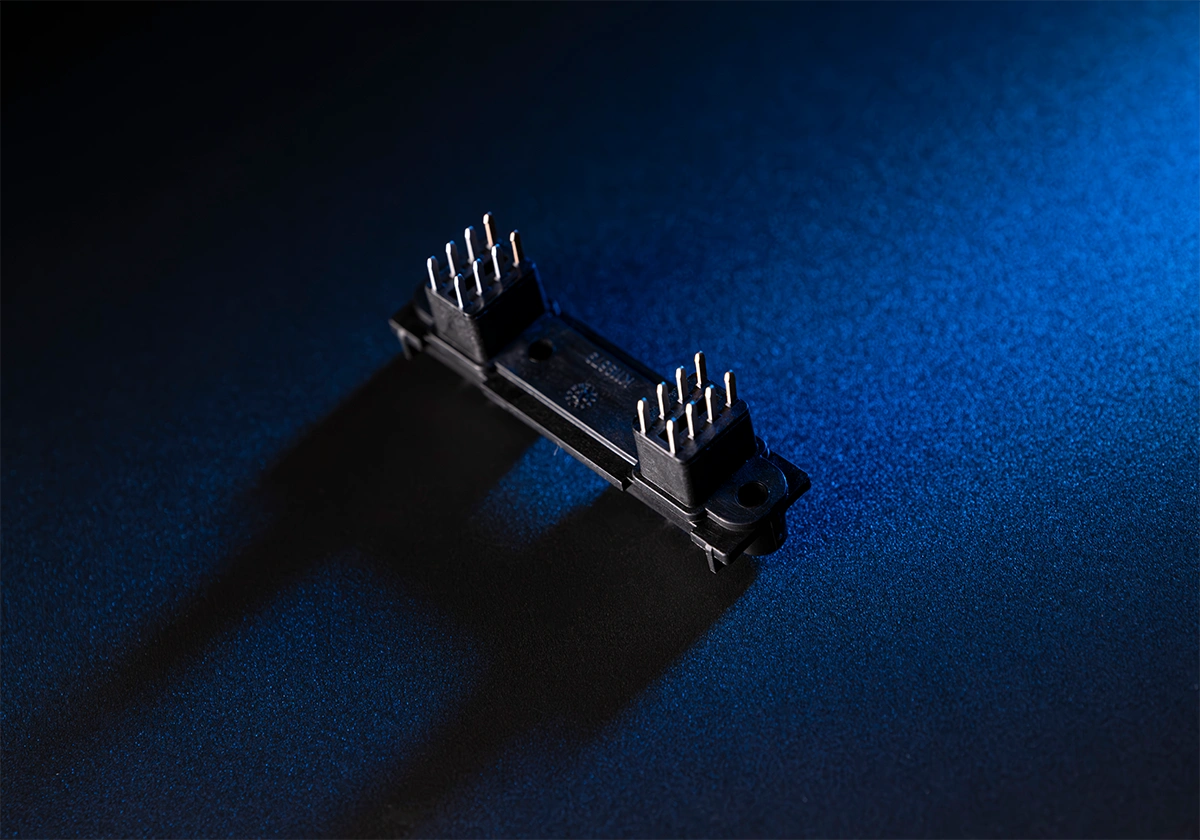

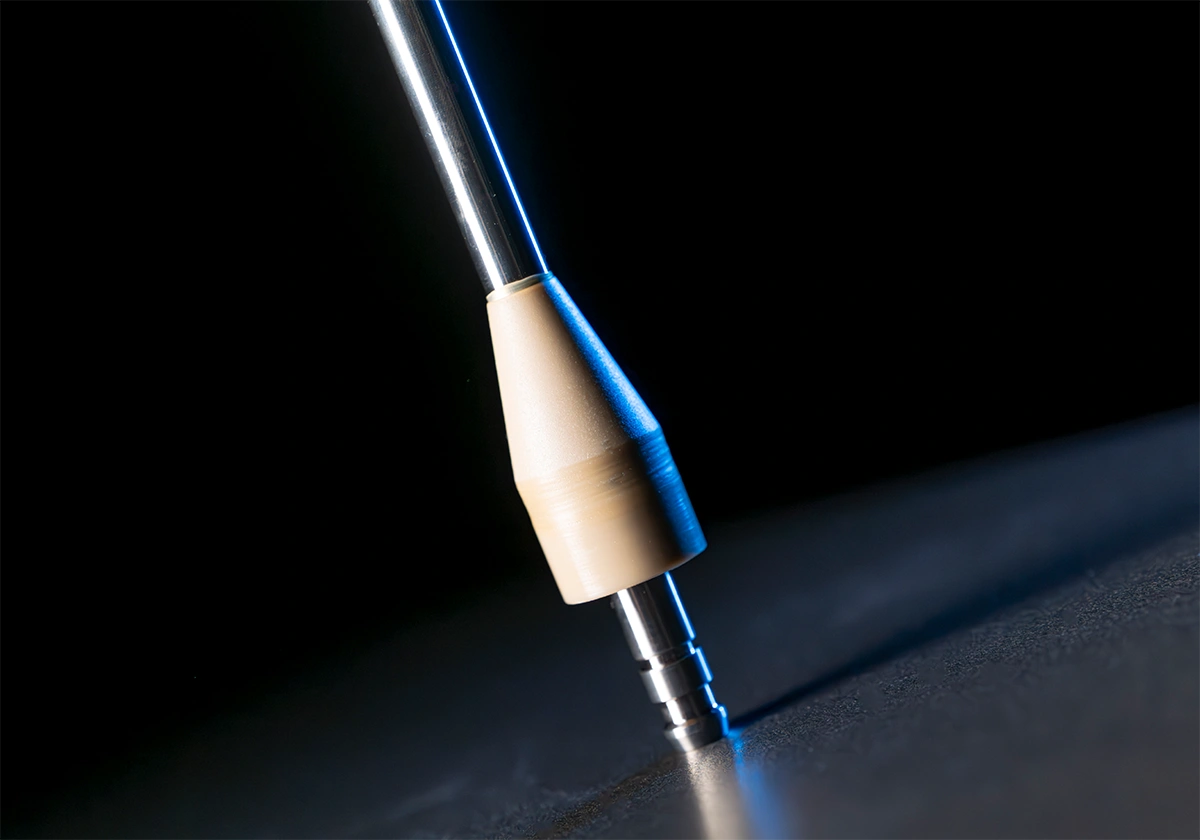

Metal Overmolding

We use a variety of processes for metal overmolding. A particular highlight is the reel-to-reel process, in which precision components are continuously injection molded onto metal strips in an inline operation. This cost-efficient method enables a reliable and precise bond between metal and plastic.

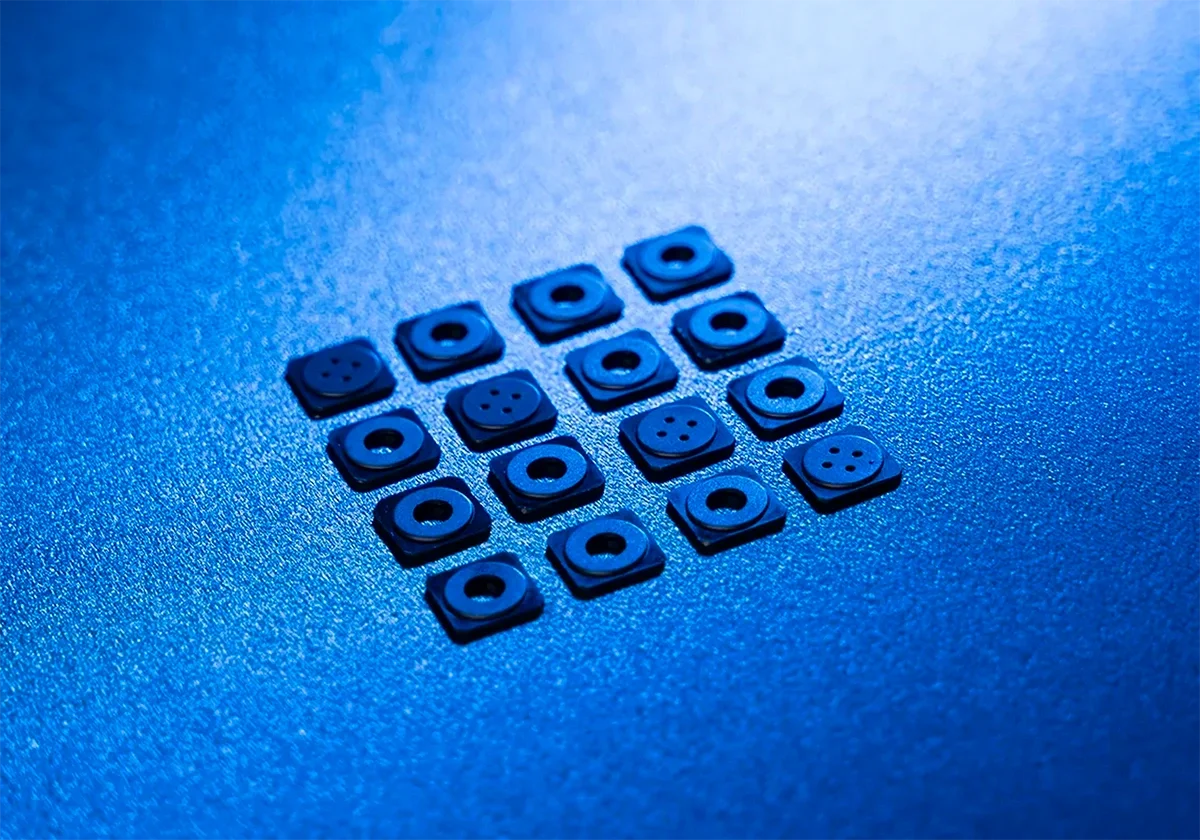

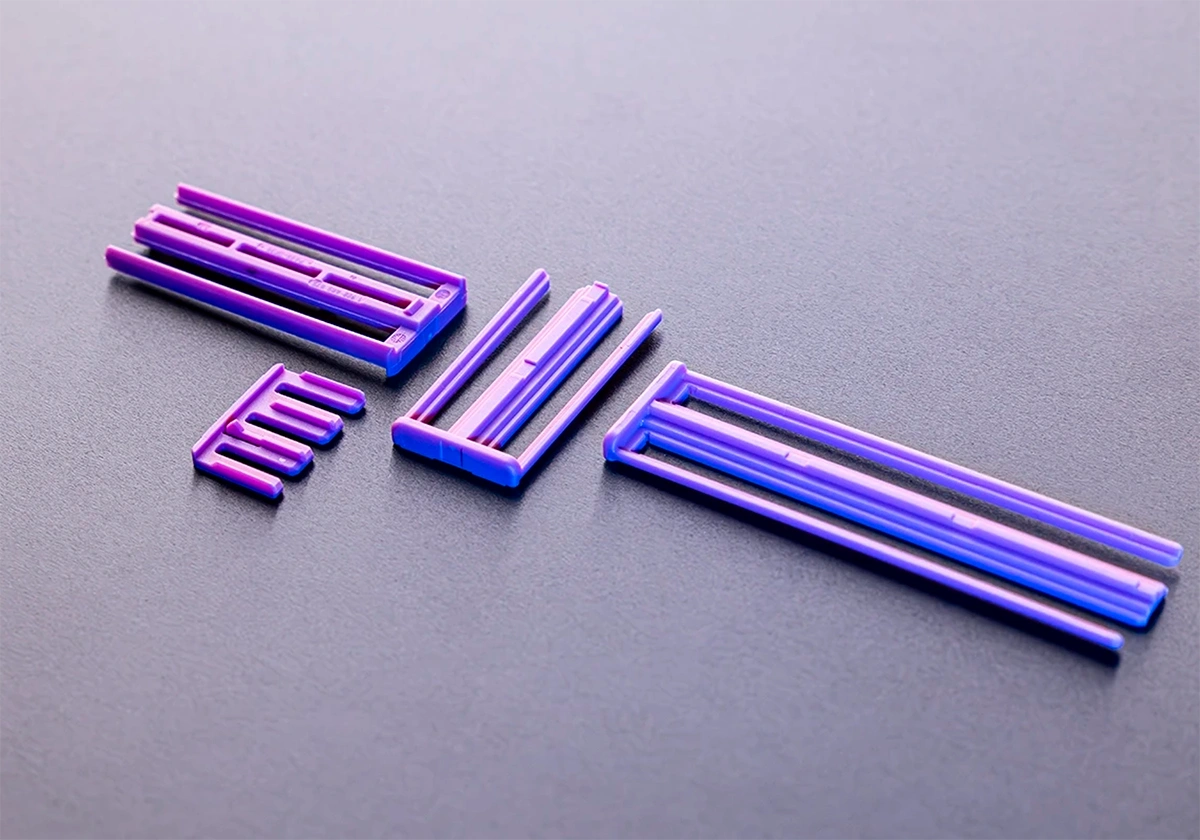

2-Component Injection Molding

Our 2-component production enables the processing of different plastics in a single step to manufacture components with varying material properties such as color, texture, and function.

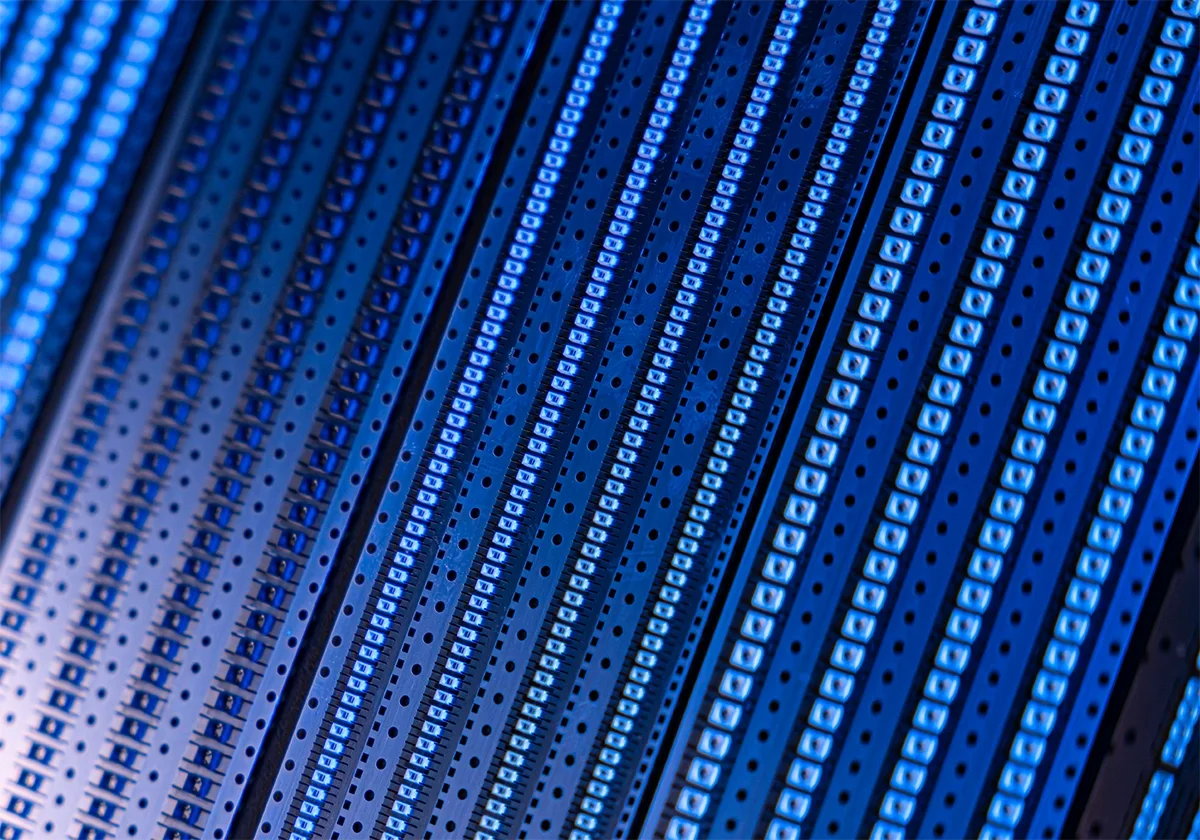

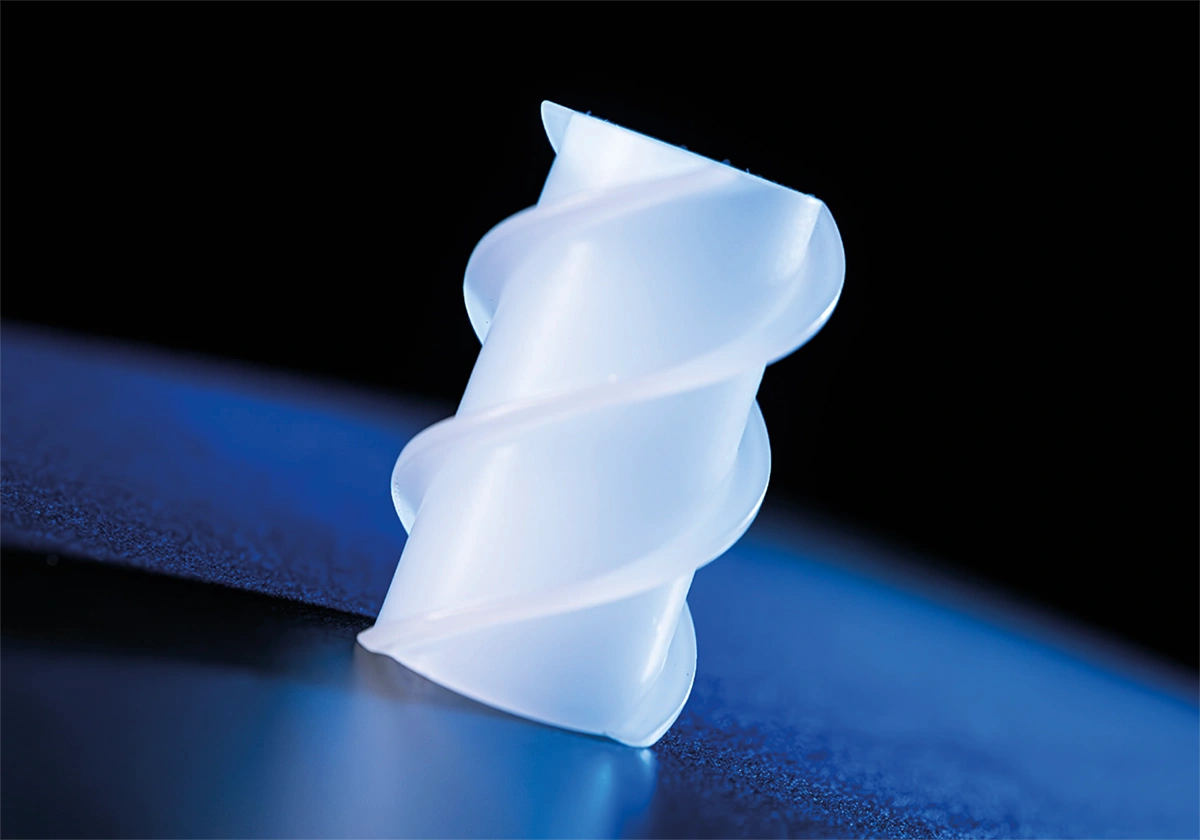

Processing of

Transparent Plastics

For visually demanding applications, we process high-quality transparent plastics with the utmost care. This results in crystal-clear components that impress not only with their functionality but also with their appearance.

Inline Punching Process

When required, we integrate a precisely coordinated inline punching process into our production line – fully tailored to our customers’ requirements.

Transfer Molding

For special requirements, we can process thermoset plastics using the transfer molding process.